Jonathan Gitlin

Additive manufacturing, or 3D printing as it’s more commonly known, is more a tool for rapid prototyping in the auto industry than manufacturing actual parts to be used on actual cars. Well, mostly. An interesting company working in this space is Divergent 3D, which has already been supplying 3D-printed parts like subframes for low-volume cars for several car companies, including Aston Martin and Mercedes-AMG.

Divergent gave rise to another startup called Czinger, which acts as something of a showcase for Divergent’s printing tech, using it to build what it says will be the world’s fastest production car. We caught up with company founder Kevin Czinger at this year’s Goodwood Festival of Speed, where among other things, we discovered Divergent has diversified its client base and is now getting into aviation, 3D printing wings for the drone maker General Atomics.

Jonathan Gitlin

We took a look at the Czinger 21C at last year’s Monterey Car Week—to quickly recap, it’s a tandem-seating hybrid supercar with 1,250 hp (932 kW) and a vast amount of aerodynamic downforce that has allowed it to break production car track records at Laguna Seca and the Circuit of the Americas.

Creating a car company to show off what Divergent’s printing tech can do seemed like an obvious move for Czinger. “You don’t know what the tools really are going to be unless you link the creation of an actual product that requires performance to the cost-productivity of the tools, the material requirements that they have,” he told Ars.

“Because, for example, to really print—not to do what people are doing today in terms of prototyping, but to do what we’re doing for the first time on the planet, which is industrial-rate manufacturing—you have to design a printer that is tuned to your material qualities, which in turn are tuned to your specification and requirements of functionality for the product, all of that needs to be designed together,” Czinger explained.

Jonathan Gitlin

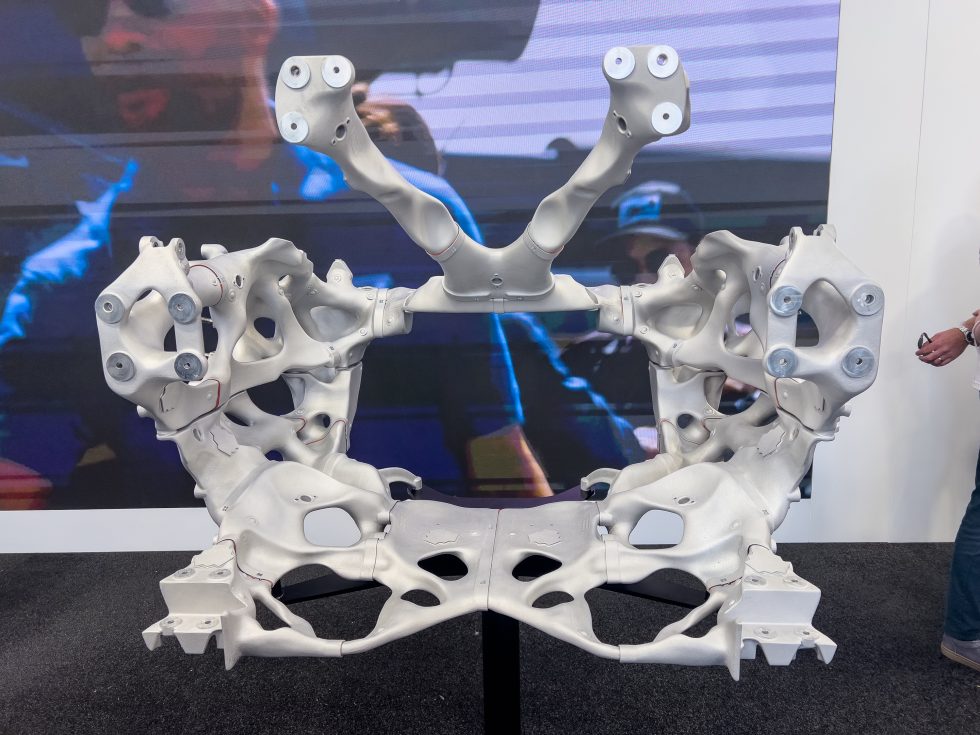

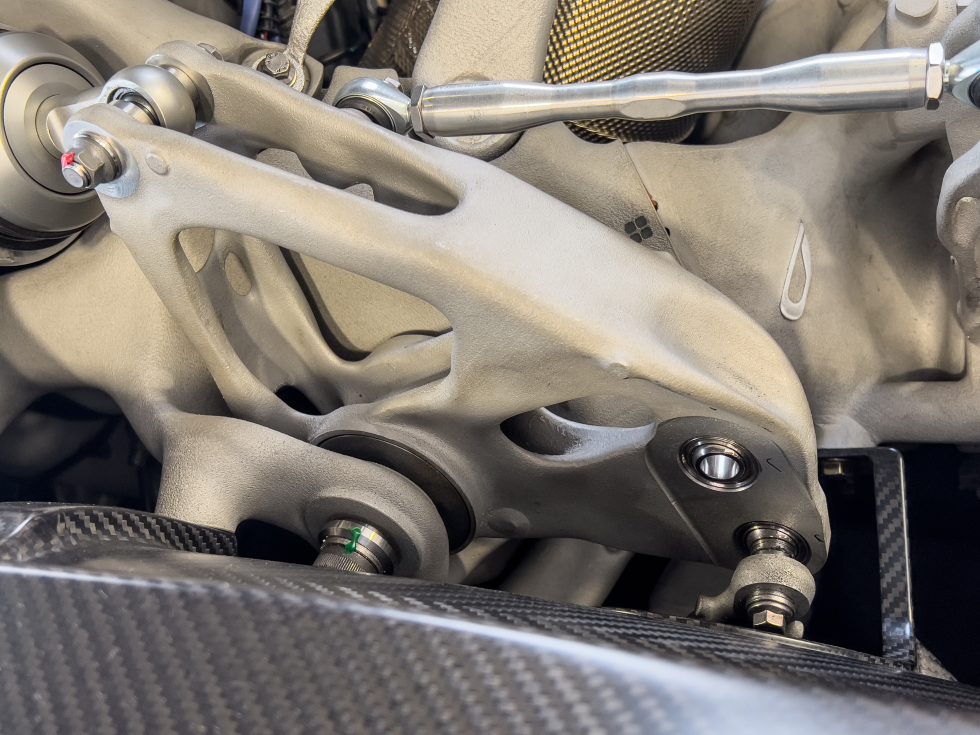

The 21C benefits greatly from the use of 3D printing—parts consolidation has resulted in significant weight savings compared to more conventional construction techniques. The resulting parts look much more organic than the mechanical bits you’d find in almost any other car, and, as an example, the brake node combines the caliper and a suspension upright but has 40 percent less mass than a more normal assembly.

“Going back to first principles, I mean, what’s really happening is, it’s very much like evolution. Nature is an energy system, right? And if you have a process of competition for material and energy, which is what it really is, then form is following function. When you go out into your garden, you see the flora and the fauna, and it looks a certain way, that’s because of that eons-long competition for material and energy,” Czinger said.

“This is using, really, the big technology innovation of the last 75 years, which is computing power—using computing power to mirror that process of optimization of requirements, performance, to minimize the use of material and energy. And it then ends up looking organic because it’s mirroring those organic process,” he explained.

Jonathan Gitlin

Czinger will start delivering its first 21Cs in the fourth quarter of this year. “it’s going to be fully crash-certified vehicle, no exemptions for North American certification. And, it’s going to be emissions-compliant for California for 2028 compliance,” Czinger told Ars.

Not just for cars

I was very interested to learn that Divergent had broadened its client base to start printing parts for the aerospace industry, too. In February, Divergent partnered with General Atomics, which makes uncrewed and remotely piloted aircraft.

“They came to us about a year ago and said, ‘We’ve spent three years designing these new smaller drones. It has about a 2-meter-long fuselage. You know we’re building it out of laid-up carbon fiber because of mass considerations, but we can’t hit our mass targets after three years, we can’t hit our cost targets, we can’t hit our production cycle because it takes 12 days to hand-lay up and build one of these,'”Czinger explained.

“Within three months using our system on the first aerospace structure we built, we provided them with flight-ready hardware that reduced the number of parts by integrating different things like fuel tanks into the skin, reduced the number of parts from over 180 to 4, we reduced mass by over 5 percent even though we were using our aluminum alloy versus carbon fiber,” he told me.

General Atomics now has more than 240 printed parts flying on test aircraft but says it’s aiming for between 30–80 percent of the parts on a small drone to be 3D printed.